![]() 小心不要被锋利的表面割伤。

小心不要被锋利的表面割伤。

基本剪裁说明

- 确保夹具安装正确,使叶片底部与轴完全平齐。在不使用任何胶水的情况下,将叶片和轴放入夹具中进行测试,并根据需要进行调整。

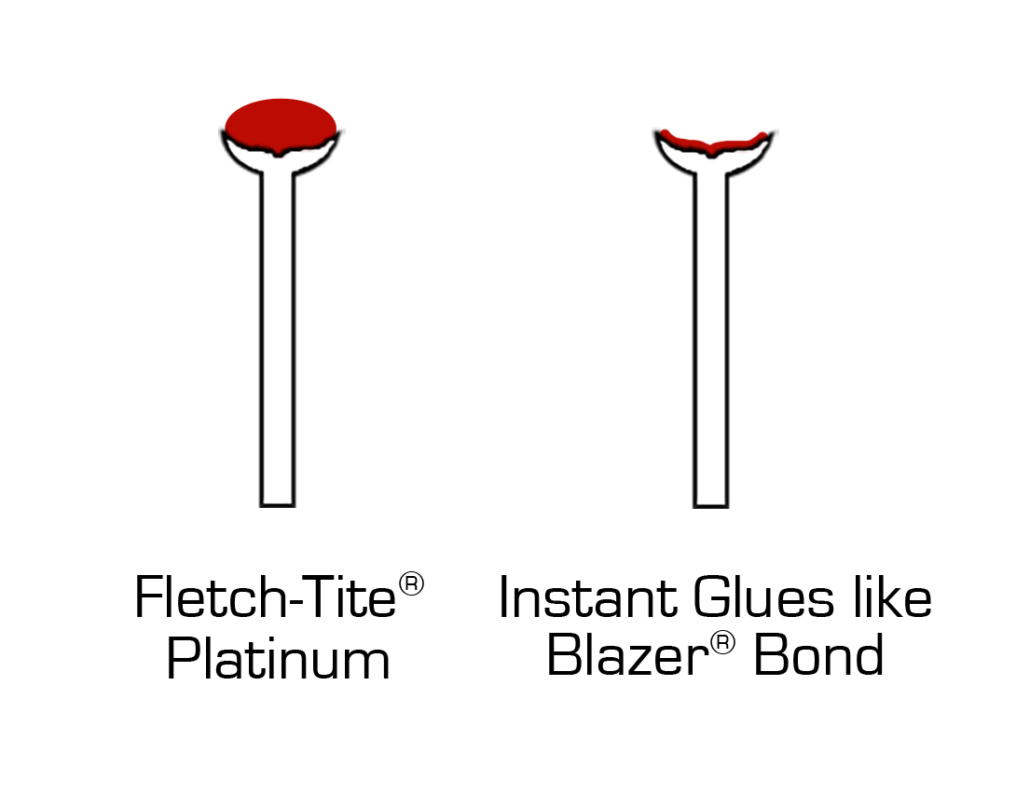

- 将叶片牢固地固定在夹具中。在叶片基座上涂抹博宁胶。请参见右侧插图以确定适当的胶水用量。

-

- 对于 Fletch-Tite Platinum 来说,使用稳定的冲程,在叶片底座的整个长度上涂满胶水。从夹具上取下后,如果叶片下方有过量的胶水挤出,下次涂抹时可稍稍减少用量 - 少量的胶水挤出也无妨。

- 对于瞬干胶,用小点胶水涂抹整个叶片的底部。从夹具上取下叶片时,如果叶片下有胶水挤出,下次涂抹时可减少用量。

-

- 按照夹具说明进行具体的箭杆插入等操作。根据胶水说明,在夹具中留出适当的夹紧时间。

- 小心地从夹具上取下箭头,在叶片的尖端和尾部涂上少量胶水以增加安全性,并根据胶水说明留出适当的固化时间。

螺旋式/偏移式箭咀

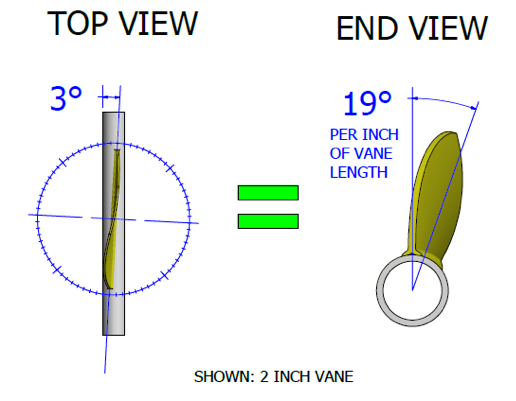

制造商使用不同的方法对螺旋/偏置进行分类,这在进行比较时可能会造成混淆。首先,让我们澄清一下,螺旋和偏移本质上是一回事。螺旋的定义是任何非 0° 直箭杆的叶片角度。偏置,简单地说,就是小螺旋,通常指 0° 至 2° 之间的任何角度。偏角大于 2° 的叶片由于其绕轴的方式而显得更加扭曲,然而,偏角小于 2° 的叶片仍然有螺旋 "扭曲",只是不那么明显而已。有两种主要方法可以确定偏移/螺旋的程度。图 A 和图 B 显示了以不同方式表示的相同螺旋。

1) 轴的俯视图:这是博宁和大多数其他制造商使用的分类方法,其中偏置/螺旋的测量与叶片长度无关。

2)轴的端视图:这是一些夹具制造商使用的测量系统,其中偏移/斜线是按叶片长度的每英寸计算的(例如 10° /英寸),使数值看起来更高。注意--该系统的测量值会随箭头直径的变化而变化。

粘合故障排除

防止粘连问题

- 正确的箭杆预处理对牢固粘合非常重要。请参考清洁箭杆页面。

- 按照所有说明进行操作,并留出适当的夹紧和粘合剂固化时间。

- 为获得 Fletch-Tite Platinum® 的最佳效果:在湿度较低(相对湿度为 30-50%)的可控环境中为箭装箭矢并使其固化。如果湿度过高(尤其是相对湿度超过 70%),我们建议使用 Blazer® Bond 或 Fletch Fuse 等即时粘合剂进行箭刃粘合。

- 确保您的箭簇区域内没有这些物品:硅基气溶胶、碳尘、油类、化学品、宠物毛发、食物、饮料等。

- 在叶片基座上使用正确量的胶水。

- 经常用丙酮清洁夹具夹钳/支臂,以防止 CA 粘合剂积聚(阻碍向下施压)。

- 确保您的粘合剂仍然有效。

识别粘附问题

如果您的叶片与箭杆完全或部分分离,以下情况可能会帮助您缩小原因范围:

轴上有粘合剂,叶片基部无粘合剂:通常表明叶片有问题。某些品牌的叶片在生产过程中使用了脱模剂,必须在上箭前清洗干净。其他品牌的叶片则需要在上箭前在叶片基座上涂一层底漆。而博宁公司的叶片则不需要这两个步骤,因为叶片底座上已经涂有底漆 - 因此,我们建议您不要清洗博宁公司的叶片。

叶片上有粘合剂,箭杆上没有粘合剂: 通常表明箭杆有问题。重复 "清洁您的箭 "页面上的箭清洁步骤,然后再试一次。有些箭杆需要额外的磨损。如果其他方法都不奏效,最好的解决办法可能是使用包裹物或对箭杆进行浸泡。

叶片和箭杆上都有粘合剂: 这可能表明夹具设置不当、夹紧时间不足或夹具损坏(如果您对夹具进行了编号,请在故障中寻找规律)。这也可能表明,在射箭之前,胶水没有按照建议的时间固化,或者箭杆或叶片上有污染物。

仍有问题? 有更多问题? 请发送电子邮件至 [email protected] 或致电 231-229-4247,我们会将您介绍给我们的内部化学家。